Our Story

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore.

A Diverse, Multi-faceted Company.

A minority-owned company itself, from its own multi-cultural workforce to its supplier relationships, MultiTech embodies the true meaning of diversity.

MultiTech’s commitment to diversity begins with the tremendous cultural, racial and gender-based mixture of employees in our workforce. Our commitment is to be a reflection of the diversity reflected in the people who buy the cars and products made by the assemblies and parts we produce. MultiTech’s commitment to diversity involves our vendors too, as our team works with several veteran-owned, minority-owned and women-owned businesses, too.

Download:

MultiTech’s Commitment

Mission/Vision

MultiTech’s goal is to be the best-in-class supplier in every parts and assembly category we enter. Our single-minded desire is that the custom mechanical components and assemblies we manufacture, plus the engineered solutions we create, perform flawlessly for every existing customer application.

This simple expectation drives every decision we make, every resource we deploy and is the key to innovation, longevity and integrity.

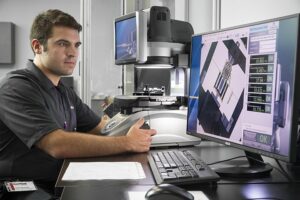

The MultiTech Difference

- Single Source Manufacturing: Multiple metal commodities under one roof provides a business case for supplier consolidation and reduction in transaction costs.

- Global Manufacturing Footprint: Extensive state of the art domestic manufacturing for every commodity we provide with offshore partnerships to leverage the best overall cost solution without any dilution to your deliverables.

- Point of Use Means Just in Time: A local facility presence allows for just in time deliveries while lowering inventory commitments and dramatic reductions on inbound freight.

- Design with Purpose: MultiTech’s SME’s (subject matter experts) help our customers engineer the most cost-effective solutions while maximizing form, fit and function.

- Diverse Assembly Options: Our Assembly facilities located in the USA, Mexico and India give our customers options when supplying higher bill of material value-added content.

- Prevention Not Reaction: A prevention-based approach to quality management impacts all, from APQP to program termination.

- Reinvesting For the Future: MultiTech believes that significant investment in our people, facilities, equipment and technology is the only road to sustainable performance.

The Leadership Team

Experienced and performance-driven, MultiTech’s well-balanced leadership team brings warmth, knowledge and perspective to every interaction.

Rahul Parikh

President

Rahul Parikh

President

The visionary and co-founder of the company, Rahul brings years of experience in both engineering and multiple-levels of manufacturing components. Rahul passionately pursues the integration of quality, manufacturing and financial management into all aspects of MultiTech's operations.

Tom Falcone

Executive Vice President

Tom Falcone

Executive Vice President

Tom is co-founder of MultiTech and a savvy manufacturing veteran of more than 40 years. His progressive mindset continually finds ways to connect customer needs with new or existing solutions. Tom's deep manufacturing knowledge, sales and management know-how are pivotal to MultiTech's growth and development.

Anthony Falcone

Director of Business Development

Anthony Falcone

Director of Business Development

Anthony has served at MultiTech for over 10 years, leading sales and marketing efforts. His customer-first mindset, combined with tremendous knowledge of all facets of the company's products and processes, bring tremendous value to each and every customer relationship.

Dustin Slawinski

Director of Continuous Improvement and Quality

Dustin Slawinski

Director of Continuous Improvement and Quality

As the torchbearer of MultiTech's commitment to quality, Dustin incorporates intensive lean manufacturing principles (Kaizen 5-S Initiatives like Gemba Walks, OEE boards, etc.) into all aspects of the manufacturing processes. This refinement combined with a zero defects mentality deliver the highest levels of efficiency and best in class quality, meaning greater product quality and savings to our customers.

Debbie Meyers

Director of Materials

Debbie Meyers

Director of Materials

One of MultiTech's longest tenured employees (19 years), Debbie knows all the in's and out's of the industry and the company's products. Her extensive background in materials management has helped turn the concept of 100% on-time delivery into MultiTech's reality.

Joel Brown

Director of Finance

Joel Brown

Director of Finance

Joel brings 20+ years of action-oriented financial leadership and the ability to develop sound, real-world strategies to Multitech's customers. His well-rounded perspective gained from the manufacturing, technology and service sectors, allow him to develop and implement predictive models and activity-based financial analysis for greater cost-savings and efficiencies.

Bryan Heller

Chief Information Officer

Bryan Heller

Chief Information Officer

Bryan brings over 30 years of executive and entrepreneurial management experience as an ERP systems integrator and operations manager. Multitech benefits from Bryan's perspective and wide-ranging, industry-tested skill set honed though the successful design and implementation of custom systems. The industries he's served are truly diverse: his expertise spans the manufacturing, distribution, shipbuilding, medical systems and financial services sector.

Brian Woods

Director of Cost and Supply Chain

Brian Woods

Director of Cost and Supply Chain

Brian brings 30+ years of procurement and management experience (21 of them at MTI alone). He has opened and managed three MTI facilities before being elevated into his current role at corporate. There, he is responsible for all elements of cost and their resulting impact to MultiTech. Brian's focus on overall business process implementation and ongoing improvement provides the foundation for achieving MTI's success-driven metrics.