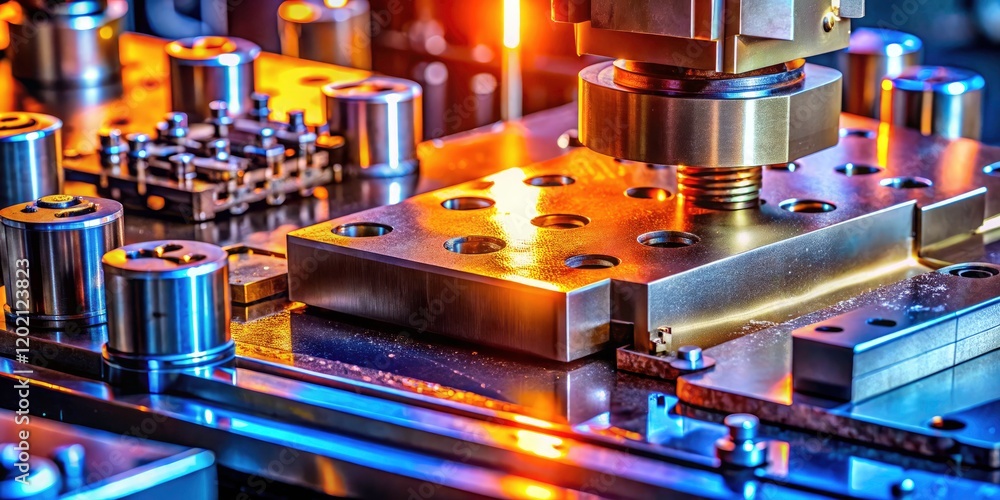

Progressive die stamping is a versatile and cost-effective technique for producing precision metal components at high volumes. During the process, a metal strip moves through a series of individual work stations, where operations such as bending, punching, and coining progressively shape the part. At the final stage, the finished component is cut from the strip, ready for use.

At MultiTech Industries (MTI), we specialize in progressive die stamping for a range of demanding industries, including automotive, aerospace, agriculture, defense, and more. With advanced presses, in-house tooling, and real-time monitoring, we deliver stamped components with the speed, accuracy, and reliability our customers require.

Benefits of Progressive Die Stamping

Progressive die stamping offers numerous advantages compared to other manufacturing methods. The process combines speed, efficiency, and accuracy, making it a preferred choice for high-volume production across industries.

Key benefits include:

- Faster production speeds. The continuous feed of strip metal through multiple stations allows many features to be formed in one pass, reducing cycle times and supporting high-volume production.

- Lower material waste. Optimized die designs make efficient use of sheet metal, generating less scrap than subtractive processes and lowering raw material costs.

- Broader design freedom. Progressive die stamping can accommodate a wide range of part geometries. The process allows multiple features, from holes and bends to more complex shapes, to be formed in sequence as the strip advances through the die.

- Dimensional accuracy. The process is designed to maintain uniform tolerances across thousands of parts, ensuring components meet specifications without extensive secondary work.

Our Progressive Die Stamping Capabilities

At Multitech, our progressive die stamping operations combine decades of tooling expertise with advanced technology to deliver precision quality, repeatability, and efficiency for high-volume production.

- Press capacity: Up to 400 tons

- Material range: Ferrous and non-ferrous metals from .005” to .250” thick, including aluminum, brass, copper, molybdenum, nickel, steel, stainless steel, titanium, and more

- Monitoring: Machine metrics via Smart Pak systems provide real-time monitoring to track production quality, performance and efficiency

Operations We Perform

Depending on your unique requirements, we design progressive dies to perform a range of stamping operations, including:

- Blanking

- Piercing

- Punching

- Bending

- Coining

- Embossing

- Drawing

In-House Tooling and Die Design

At MTI, high-quality stamping starts with high-quality tooling. We design, build, and maintain all of our progressive dies in-house, giving us full control over accuracy, consistency, and lead times. Our in-house tool room features CNC machining centers and advanced wire EDM systems, operated by experienced toolmakers who ensure every die is built with quality in mind and for long-term sustained performance.

This in-house approach shortens development cycles, reduces downtime, and allows us to adapt quickly to customer design changes. By keeping tooling and stamping under one roof, MTI delivers high quality, cost-effective production without the delays of outsourcing.

Value-Added Capabilities

To supplement our progressive die stamping capabilities, MTI provides a range of value-added services to streamline production:

- Wire EDM

- CNC machining

- Deburring

- Laser cutting

- Plating, passivating, and heat treating

These capabilities allow us to manage projects from start to finish, reducing outsourcing, shortening lead times, and ensuring consistent quality.

Engineering & Quality

Engineering and quality are at the core of MTI’s progressive die stamping operations. Our in-house engineering team works closely with customers from the earliest stages of design, reviewing applications, materials, and production requirements to ensure the manufacturability of every part. By getting involved early, we help optimize both product design and the tooling required to produce it, reducing lead times and minimizing costs.

Quality is built into every step of our process. MTI’s facilities are equipped with advanced inspection systems and follow prevention-based quality management practices such as APQP and in-process monitoring. We maintain certifications to international standards, including IATF 16949:2016 and ISO 14001:2015, and operate with a zero-defect mindset that drives consistency across high-volume runs.

Partner with MultiTech Industries for Your Progressive Die Stamping Needs

At MultiTech Industries, our progressive die stamping services are backed by state of the art in-house tooling, advanced press technology, and expert engineering support. Offering these capabilities under one roof allows us to streamline production, control costs, and maintain consistent quality. With decades of experience and dedication to quality, MTI is a trusted partner for manufacturers that demand precision and reliability.